WorkBench Electronics Prototyping and Project-Building System by Phase Dock Inc

2021-06-09 | By Werner "Chris" Lehenbauer

Mount, manage, protect, and transport electronics, projects, and prototypes.

When we ask people what they use to put their electronics projects together, the answers are not surprising: hot glue, plywood, rubber bands, LEGOs, zip ties, “nothing”, “hope”, and “gravity”.

We’ve heard stories about projects breaking on the way to class, with a final grade in the balance. Or Thanksgiving dinner at risk because the dining table is covered with electronics too fragile to move. Or the boss-lady telling the firmware team to “clean up this mess.”

Just google “electronics projects” or “Arduino projects” and select “images”. It’s a common situation.

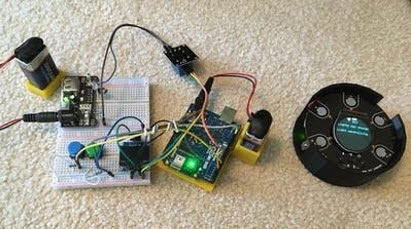

Our good friend André had this great build in progress on his desk for weeks. When asked about it, André complained that he couldn’t move anything without breaking it. He had already pilfered his wife’s cutting board (photo), but it wasn’t helping.

If you’ve been working with electronics for any time at all, I’m sure you are dismayed with the wide array of PCBs and myriad other electronics components such as relays, speakers, sensors, breadboards, displays, and so on. It seems like no two components use the same mounting-hole pattern or are the same size or shape.

Do you simply set the components on your desktop and start to wire them up (and then just pray that the project never has to be moved)? Do you mount your electronics on plywood, hoping that you won’t have to rearrange them (but you know you will)? Do you worry about protecting the delicate underside of PCBs or accidently shorting or breaking connections? Are you embarrassed to show your project to peers, your professor, or your customer? Do you really have the time to design and build a transportable and protected work platform or enclosure?

This is not really what you signed up for, is it?

An exhaustive Internet search yielded very little in terms of a solution, so I was inspired to solve the “problem” of electronic components—non-standard shapes and sizes, fragile connections, lack of portability, and desire to be able to quickly and easily reorganize any project layout.

The result? The WorkBenchTM Project Development Kit from Phase Dock.

WorkBench is an ecosystem of mechanical components that greatly accelerate and simplify the process of teaching electronics or creating prototypes and projects. Think of it as “a breadboard of breadboards.”

WorkBench makes it possible to quickly prototype or build almost anything you can imagine.

You choose the best electronics for your purposes. WorkBench helps you mount, organize and protect them all.

WorkBench accelerates project building, by minimizing the time and creative energy previously spent building ad hoc project platforms or repairing inadvertent damage. WorkBench secures and protects your project while you work on it and when you deploy it.

Phase Dock WorkBench projects are backpack proven. (Video source: Phase Dock)

Cat owners protect their projects with handy covers. (Video source: Phase Dock)

Fearlessly take your project anywhere. (Video source: Phase Dock)

Clicks keep your components locked in place—until you intentionally release them. (Video source: Phase Dock)

Who can benefit from WorkBench?

Technical Professionals

- Improves productivity and efficiency; enables more iterations, more tests in less time.

- Presents a professional appearance for clients and colleagues.

- Transitions easily to field deployment.

Makers and Hobbyists

- Get to the fun part of the build more quickly.

- Experiment and build more cool projects in the same amount of time.

- Keep the peace at home with a neat and organized workspace.

Students and Educators

- Minimize class time lost to setup and teardown.

- Accelerate learning with hands-on projects.

- Backpack-proven. Secure portability and storage for projects.

How does WorkBench accelerate innovation and minimize frustration?

Seems like no two components use the same mounting hole pattern or are the same size or shape. WorkBench standardizes the interface for PCBs and other electronics components such as relays, speakers, sensors, breadboards, displays, and so on. How is this possible?

The Matrix and the ClickTM connector create a standard interface

By establishing a standard interface between electronics and a platform, WorkBench gives the user the ability to arrange, rearrange, and organize components quickly.

The Matrix is Phase Dock’s open-standard pattern of holes, precision laser-cut into each WorkBench Base. WorkBench Bases come in many shapes and sizes for desk-top work, field project deployment, or wall-mounted showcases—but they all use the same Matrix pattern.

(Image source: Phase Dock)

(Image source: Phase Dock)

The primary hole pattern of the Matrix is 9.55 mm (0.375") diameter holes on 25.00 mm centers in both the X and Y directions. These holes mate to the feet of the ClickTM connectors used to mount your electronic components.

The secondary hole pattern is 4.35 mm (0.171") diameter holes also on 25.00 mm centers, offset in X and Y from the primary holes by 12.50 mm in both directions. These smaller holes are designed for M4 or #8 Imperial screws and allow for a wide range of attachment options beyond the Clicks.

The four legs on the ClickTM connector snap securely into the primary holes in the Matrix. Two of the feet are “fixed”; two of the feet have a spring mechanism that enables them to “lock” and “unlock” into the Matrix. Clicks come in a range of sizes to mount the smallest relay, on up to large boards such as the Jetson Nano.

To operate the Click, the user simply inserts the fixed feet into the Matrix, then gently squeezes on both “locking” feet while pushing the Click gently down into the Matrix. Once seated, the Clicks resist extraction from the Matrix—until the user intentionally releases them by reversing the process.

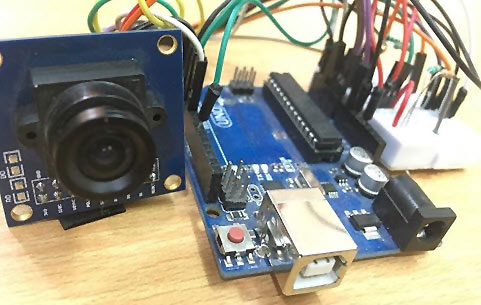

You mount the electronic component (for example, an Arduino) onto a Click connector either directly, or using a SlideTM adapter. It takes a few minutes, but you only need to do it once. Now the Arduino is equipped with a standard-mounting capability and the underside is protected from damage.

Users can snap the Click-mounted Arduino onto any WorkBench Base, in any location or orientation. It stays securely in place until intentionally released.

Assembled projects stay assembled—whether stored in a classroom or engineering lab, at home or even carried in a backpack.

SlideTM adapters enhance convenience and elegance

Slides are mounting adapters that can be attached to the Click connector.

The Slide may protect the underside of a PCB, or enable easy mounting of potentiometers, cameras, LORA antennas, displays, or almost anything the user can imagine. Slides are a convenience, not a necessity. Many electronic components can be mounted directly to a Click or even to the WorkBench Base itself.

Slide adapters are available through DigiKey for the most popular single-board computers and microcontrollers. Any PCB that shares the same mounting hole configurations can use the Slide, such as the Arduino Uno, Sparkfun Redboard, and the Seeeduino family of boards.

Slides available today:

- Arduino (Uno and Mega)

- Raspberry Pi (2/3/4 and Zero)

- Feather/Particle

- BeagleBone Black

- Jetson Nano

- Circuit Playground

The rich WorkBench ecosystem is expanded with open-source Slide adapters

Phase Dock fans are beginning to design innovative Slides to expand the usefulness of the WorkBench ecosystem. In addition, many Slide adapters for field-programmable gate array (FPGA) PCBs used extensively in academia (such as Terasic and Digilent) are open source.

Phase Dock posts the open-source STL files to Thingiverse, empowering users to 3D print these Slide adapters and encouraging them to invent their own.

Adjustable Slide for camera mount

Adjustable Slide for camera mount

Slide for LORA board and antenna mount

Slide for LORA board and antenna mount

Slide for potentiometers or input/output jacks

Slide for potentiometers or input/output jacks

In addition to DIY-printing adapters, users are encouraged to hack the WorkBench:

- Drive screws, cut or Dremel the Clicks or Slides

- Attach DIN rail to the Base, or to the Clicks

- Glue LEGO base plate to a Click to take advantage of Seeed Studio’s mounting adapters

- Use glue, zip ties, or hook & loop fasteners

- Leverage the secondary matrix in the Base to attach other components, or manage wires and cables

Security and storability is the proverbial icing on the cake.

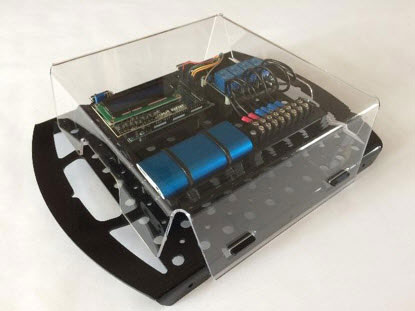

WorkBench accessories make it even more useful.

- Covers: two sizes of the WorkBench come with clear acrylic covers to protect your work from curious fingers or paws. (Cat owners love the covers!) Covered projects are backpack-proven, too.

- Small parts storage: Storage options (including an integrated tacklebox) help project builders corral components before, during, and in between builds.

(Image source: Phase Dock)

(Image source: Phase Dock)

- Multi-project storage: Hang projects on the wall, store on racks, or stack on shelves.

(Images source: Phase Dock)

(Images source: Phase Dock)

- Enclosures for outdoor or rough use: WorkBench offers a weatherproof enclosure option for field deployment. (See Bud Industries boxes)

Download the free eBook at https://PhaseDock.com/Electronics-Mounting-Guide.

More information at https://www.digikey.com/en/supplier-centers/phase-dock-inc

Phase Dock Inc.

Raleigh, North Carolina, USA

info@PhaseDock.com

https://PhaseDock.com

Phase Dock® is a registered trademark of Phase Dock Inc.

Phase Dock WorkBench™, Phase Dock Click™, and Phase Dock Slide™ are trademarks of Phase Dock Inc.

Copyright © 2021 Phase Dock Inc.

Phase Dock founder and manufacturing engineer Chris Lehenbauer is a USAF-trained machinist, degreed computer scientist, professional woodworker, injection mold builder, and mechanical problem solver. He has helped build UAVs, flying cars and medical products—and he maintained the fastest manned production aircraft ever built –the SR-71 Blackbird.