The Importance of Good Crimp Tools

The electrical contact is the most important part of any connector, from the humblest Molex KK Plug to the most complex automotive receptacle. For a contact to provide the best possible performance, it is vitally important that it is terminated correctly.

For most cable applications, the user is presented with a choice between crimp or solder techniques. Crimping has been common since the middle of the 20th century, and it offers several key advantages to the user:

(Image source: Molex)

(Image source: Molex)

(Image source: Molex)

(Image source: Molex)

1. Reliability: A well-made crimp termination combines good electrical conductivity with a reliable mechanical joint. The termination must provide the lowest possible electrical resistance, while still retaining the highest possible strength to prevent the possibility of damage during use.

2. Ease of operation: Crimp terminals use dedicated tooling that is designed to be easy to use. Hand tools, these can be used in field and workshop environments, making them ideal for operators who must work under difficult conditions. Unlike solder joints, crimping does not require high temperatures or potentially hazardous materials, making it an ideal solution for enclosed or difficult to reach locations.

3. Repeatability: Unlike soldering operations, crimping offers advantages in operator efficiency. Using the correct crimp tool, it is possible to produce a consistent termination without the need for specialized soldering skills. The amount of training required to operate a crimp tool is less than that of a soldering iron, allowing assemblers to concentrate on working rather than learning.

The Right Combination

The ideal crimp joint combines low electrical resistance with good mechanical strength. To achieve this, the wire of the cable is compressed within the crimp terminal to provide the best electrical conductivity. The crimping process will deform the strands of the wire so that there is a gas-tight joint. Not only will this provide the greatest surface area for electrical contact, but it also prevents oxygen or moisture from reaching the metal of the wire and terminal, reducing the possibility of corrosion.

Insufficient compression during the crimping process will not provide this gas-tight seal. This means that the electrical resistance of the joint is higher than desired, making it less efficient. This has the potential to be dangerous, especially where the terminal is used for power circuits. A terminal with a high electrical resistance will generate excess heat when sufficient power travels through it. In extremes, this may exceed the safe working temperature of the connector, leading to anything from plastic parts melting to a possible source of fire.

In addition to the electrical properties of the terminal, it is important to consider its mechanical strength. The crimping process ensures that the wire is secured firmly within the terminal so that it can withstand the use for which it is designed. A joint with insufficient compression will not retain the wire within the terminal with enough force to prevent it from falling out or being pulled out. In contrast, however, compressing the wire too much will weaken the mechanical strength of the wire, and will potentially damage the terminal. This may lead to the same problems occurring.

It is therefore vital that the terminal be crimped with the correct amount of force to ensure the best electrical connection with the ideal mechanical strength. Manufacturers like Molex understand this, and so developing a new electrical terminal will go hand-in-hand with the development of its tooling.

(Image source: Molex)

(Image source: Molex)

Part of a System

In fact, it can be said that the terminal itself is only part of a system that includes the wire, the connector into which it will be fitted, and the crimp tool that is used to terminate it. Without any one of these elements, the system will not perform correctly.

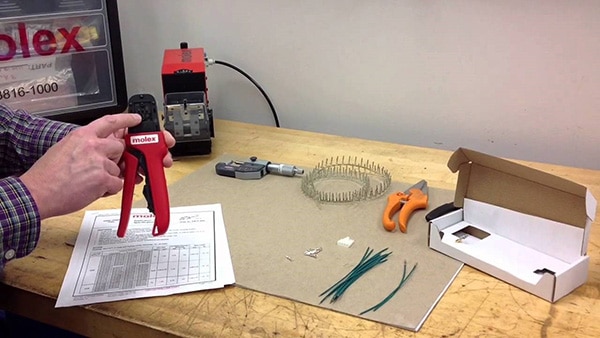

While it may be the most expensive part of this system, the value of a dedicated crimp tool is that it has been created to perform several complex operations whilst being simple and straightforward to use. The jaws of the tool shape the metal of both the terminal and the wire in such a way to create the ideal gas tight seal. At the same time, to minimize errors, the positioner is designed to hold the wire in the ideal position while crimping to minimize errors. This precision comes only with dedicated crimp tools that are designed in conjunction with the terminals.

A good crimp tool is not just about the jaws and positioner, however. Operator convenience and comfort are an important consideration when selecting the right tool, and Molex crimp tools have been created with this is mind. Many of the tools offered by Molex feature interchangeable dies to provide the user with flexibility and value for the money. Some tools even allow the orientation to be changed to allow for left-handed operation. For a greater understanding of the features offered by Molex dedicated crimp tooling, take a look at this video.

Choose Your Crimp Tool Wisely

Crimp termination provides reliable and robust electrical connections for every application. However, it is important to remember that the crimp terminal is just a small part of a complete system. Without the correct crimp tool, the system is compromised, and cable termination is left to chance. By choosing the right crimp tool for your application, you can take advantage of the expertise of the manufacturer and ensure that your cable terminations are safe and secure for years to come. Make sure that you are up-to-date with the latest range of Molex crimp tools on DigiKey’s dedicated application tooling page.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum