DK Tech Talk - Volume 6

Application Tooling

I spent a couple hours yesterday in a room with some of our representatives from Molex. A big topic of discussion was application tooling. More specifically, the differences in tooling that they offer for some of their contacts. An example of this would be Molex part WM13478-ND. This is a contact from one of the Mini-Fit Jr 5558 housings. When you look at the hand tooling for this contact you see three different crimp tools at three different price points: WM9999-ND, WM17551-ND and WM24837-ND.

(Image source: Molex)

(Image source: Molex)

Having three recommended hand tools can lead to some confusion as to what you want to buy and why would you want to spend more money on a tool for the same part. Let’s look at a couple of the tool’s features and benefits.

The WM9999-ND is a popular tool, mostly because of its price point. As I write this, the crimp tool is a little less than $75 USD. The tool is handy and honestly, we have one in our lab here at DigiKey for prototyping purposes. If you take a look at the specification sheet (https://www.molex.com/pdm_docs/ats/ATS-638111000.pdf) for the tool you will see that it can handle a wide variety of contacts from 14-24 AWG; and it does well.

Now for a little bit of bad news. Because the tool is so universal, it is not really user friendly and you really need to watch your crimps. You also will have to crimp the insulation and the wire tabs on the contacts separately. This can be done, however, since the insulation tab is only 1.2 mm wide and the wire tab is only 2.1 mm wide and there is less than a mm between them, it takes a little finesse to make sure you are crimping one without crimping the other. The tool also does not ratchet so it is a bit of a guessing game to make sure you are getting a decent crimp. Why would you buy one then? It’s easy. If you only have 1 or 2 contacts to crimp for a prototype or possibly a one-time repair, this is the tool for you. I would, however, recommend you spend a little extra. If you need to crimp one contact, I would buy 5 to 10 to ensure that you get a good quality crimp that works in your housing.

Next, we have the service grade tool WM17551-ND. What is service grade? It is just what the name says. This is a tool that is designed for the employee who is going to service an existing part. Someone who will likely make a couple crimps in a day, however not someone who is going to be crimping contacts all day for a manufacturing application. This tool is going to be approximately double the price of the universal tool, but the upgrades are worth the money if it will be used multiple times.

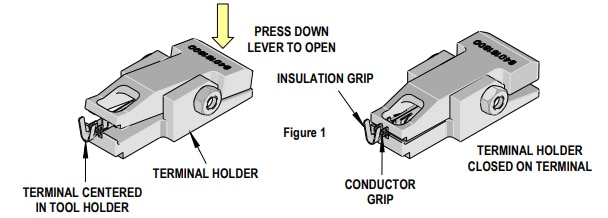

There are three main upgrades when I look at the service grade tool. First is the terminal holder. Pictured in the specification sheet (https://www.molex.com/pdm_docs/ats/ATS-640160200.pdf) you can see how this tool holds the contact in place while you crimp. The holder is held in place magnetically and can be lined up with the correct slot for the wire gauge you are using. Again, because the terminals are small and you must line up the contacts, it can be a little bit of a struggle to line up correctly. Once lined up, the second benefit is that when you crimp you will crimp both the insulation tabs and the wire tabs of the contact at the same time. While crimping you will also see the third benefit, which is the ratcheting handle. The ratchet insures that you make a complete crimp without over crimping the contact.

(Image source: Molex)

(Image source: Molex)

Using the service grade tool in the training session, it was an upgrade from the universal WM9999-ND. However, I did have to make two crimps as my first contact was not lined up correctly. This was my error. However, I still felt that the tool could use some fine tuning.

Fine tuning was exactly what I got when we used the premium grade hand tool WM24837-ND. Not only does it have the ratchet feature of the service grade tool, the handle is upgraded and easier to hold with one hand. The universal terminal holder that is magnetically held on the service grade tool is upgraded to a fixed terminal locator. When you go to use the premium tool, you push the button on the back of the locator, and it springs forward so you can easily seat your contact in the appropriate locator hole. This is also shown in the specification sheet (https://www.molex.com/pdm_docs/ats/638190901-000.pdf) for the crimper. The terminal is held in place as you release the button. After that you slide in the wire and crimp, the ratcheting feature makes sure you crimp both tabs fully in one easy crimp. With this tool there was no question and the first time I used it I received a quality crimp. Again, the price point is about double that of the service grade tool. However, if you are going to have someone crimping multiple times a day or part of their everyday work, it is well worth the money for the ease of use and quality, repeatable crimps.

I know this may feel a bit like an advertisement for Molex, however I mainly wanted to point out the differences in the grades of hand tooling they provide. If you have any questions of comments on hand tools, let me know in the comments section below.

Let’s look at some of the recent content on DigiKey.com

Maker: Shawn Hymel has a project on Making a Temperature Logger with the Adafruit Feather STM32F405 Express. Shawn goes through the components, hardware hook-up and coding. Bonus on this board as it can be done in either CircuitPython or C.

Blog: Over on TheCircuit, Ashley has compiled the 2019 Holiday Gift Guide. The guide includes several neat items that DigiKey carries that are sure to be on any electronics enthusiast’s gift list.

Article: Brand new in our Article library is another great piece from Bill Schweber on Energy Harvesting vs Batteries for Multidecade IoT Sensor Operation. Bill goes into the benefits and challenges of powering some IoT devices over long periods of time.

TechForum: A couple new posts recently on the TechForum include Kelsie in our IoT category talking about What is Zigbee? Paul also has post on Crimping Ring Terminals in which he shares information on crimping, as well as additional articles that talk about ring/stud sizing and preparing your wire for crimping.

Yeah, we sell That!

Oven? Well not the “cook your turkey” oven, however, we have Mini Crystal Ovens. To be honest, when oven was first mentioned to me as an item, I was thinking about an oven to bake parts. That is not the case either. These mini ovens are made to help regulate a specific device temperature. As you know, many if not all parts have slight performance variations over temperature change. Many also create heat as they operate. The point of these mini ovens is to help regulate the temperature of these devices to help mitigate the performance changes.

(Image source: Taitein)

(Image source: Taitein)

Next is an item many people use: headphones. While we have come to know PUI for the speakers we sell, we recently started carrying a set of headphones with in line volume controls - part number 668-PUIAUDIOHEADPHONES-ND.

(Image source: PUI Audio, Inc.)

(Image source: PUI Audio, Inc.)

Inside the walls of DigiKey

Not just inside our walls, however still a popular topic here at DigiKey is our annual DigiWish Giveaway. In this recent press release, DigiKey Launches 11th Annual DigiWish Giveaway, we explain how participants can go on social media and use the hashtag #DigiWish and tell us their wish. Everyday we give away a product valued at up to $100 to a random DigiWisher. I always find it fun to follow the posts and see what people are wishing for. Sometimes it even gets me looking at more products I am not familiar with or didn’t even know were hiding in the corners of our site.

Thank you for stopping by and as with all the content I write, I am open to discussion, questions, and contributions. Please feel free to comment below or send me your DigiKey questions so I can answer them in the next edition.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum