Without the Use of Double-Cell EEPROMs Data is Easily Lost

As an engineer, much of your career is accompanied by a series of personal laptops. I started with the IBM ThinkPad line because they had a very solid construction and were highly reliable. I once had a ThinkPad 560X which was as portable as they came 20 years ago, with no CD or floppy disk (remember those?). It was eventually replaced with another laptop, and another, and on it went.

About ten years ago I decided to put together a digital home stereo system that would be controlled by a nice compact laptop that would not take up much shelf space. It made sense to repurpose old hardware for the task. Serving audio out of the built-in 3.5 mm drive was no problem for the Pentium in the ThinkPad 560X, so I pulled the laptop out of storage and built my home audio system around it.

One bright Sunday morning I booted the laptop so I could have Meat Loaf blasting out of my speakers while I sipped my coffee. It was a normal Sunday morning until seconds later I heard from the ThinkPad’s speakers:

BEEEEEEEP! BEEEEEEEP!

Those of you familiar with the old BIOS system will recoil in horror at the sound of the laptop power-on self-test (POST) beep of doom. I looked at the screen and saw a three-digit error POST code.

Going to my daily driver laptop I looked up the error code, hoping that maybe the laptop had decided it didn’t like my taste in music. Alas, the code told me that the EEPROM used to hold the BIOS configuration was no longer interested in retaining its data. Multiple reboots were fruitless—it was gone.

Further investigation revealed that the ThinkPads back then stored their BIOS configuration data in a serial EEPROM soldered onto the mainboard. EEPROM technology was still evolving back then, with semiconductor manufacturers working diligently to make their devices faster and more reliable while improving data retention and lowering costs.

I kept the laptop in storage, occasionally turning it on and hoping it would surprise me by booting, but like any good relationship gone bad, the good ol’ days were gone.

Today, EEPROM data retention is more important than ever. With the Internet of Things (IoT), Industrial IoT (IIOT), and nodes demanding much longer data retention with improved reliability, EEPROM manufacturers have made significant improvements that allow data to be secure for decades.

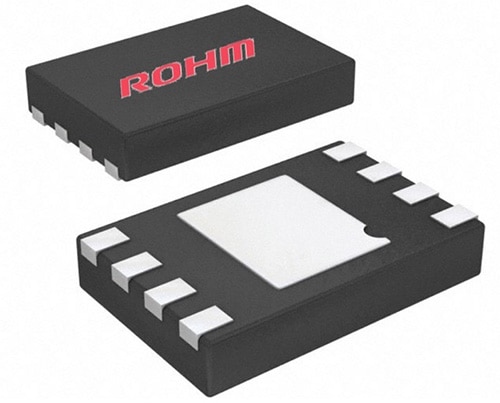

For example, Rohm Semiconductor offers a selection of automotive-grade EEPROMs that are designed for a very long life of data retention and reliability. The BR24G64NUX-3ATTR is a 64 kilobit (Kbit) automotive EEPROM with an I2C interface that Rohm has specified for more than 40 years of data retention and over one million write cycles. It comes in an 8-pin UFDFN exposed pad package (Figure 1). The I2C serial interface can interface to a host microcontroller at 1 megahertz (MHz) with a VCC range from 1.7 to 5.5 volts.

Figure 1: The BR24G64NUX-3ATTR is a 64 Kbit EEPROM with a double-cell memory structure that can retain data for over 40 years. (Image source: Rohm Semiconductor)

Figure 1: The BR24G64NUX-3ATTR is a 64 Kbit EEPROM with a double-cell memory structure that can retain data for over 40 years. (Image source: Rohm Semiconductor)

The BR24G64 EEPROM family has several data protection features. A write protection (WP) pin allows an external circuit to impose hardware write protection of the EEPROM data. When WP = GND data writes are allowed. When WP = VCC all data writes are blocked to the EEPROM memory array. Reads are allowed, as are reads and writes to internal registers. This can be used to help prevent the microcontroller host firmware from writing to the EEPROM during an external event that may conflict with a write operation.

Many EEPROM single-bit failures do not occur during normal operation but during the short power-on and power-off events. These events generate spurious low voltage transients which can lead to an inadvertently spiked write signal being applied to an EEPROM cell, resulting in a single-bit failure. To prevent this, Rohm’s automotive EPROMs have two internal protection circuits. The power-on reset protection circuit waits until VCC has ramped up to a minimum internal voltage, after which it then applies VCC to the rest of the chip. This prevents internal low voltage transients and ensures the EEPROM memory array is not corrupted during power-on events. The second is an undervoltage protection circuit to prevent extraneous writes to memory when VCC drops too low. If VCC falls too low below the minimum operational voltage, the EEPROM resets itself to prevent an EEPROM spurious write.

EEPROM data memory is designed for fast read operations and a relatively fast write. EEPROMs write data to a memory cell by passing electrons through a tunnel-oxide film. The film can degrade over time and temperature, and the film is weakened with every cell write. Even in storage, high temperatures can degrade the film. Eventually, the cell will degrade, resulting in a memory bit failure which will keep the cell stuck at a logic 1. This is why EEPROMs over the years have been plagued with single-bit memory failures, which is what happened with my ThinkPad 560X when I booted to play Meat Loaf. With the EEPROM gone, the 560X gave me a code for a checksum failure, the sad end due to a single-bit failure.

Rohm’s automotive EEPROMs use a double-cell structure for each memory bit. A sensing circuit monitors the state of the first cell. If the cell is close to failure, the second cell will step in while the first cell is deactivated. While this increases the die size, it results in 40 years of data retention and over one million write cycles. Well, two out of three ain’t bad.

Conclusion

If Rohm Semiconductor’s high-reliability automotive EPROMs had been around 20 years ago my ThinkPad 560X would still be shouting out music, instead of going Beep! Beep! to an ill-deserved demise on that bright Sunday morning.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum