Data Management with SmartSolutions™

The importance of data

For years, manufacturers have known the importance of data but relied on collecting it manually: this means a dedicated person walking from machine to machine, writing down productivity rates and scrap quantities, then transferring these metrics to whiteboards for staff to view. The same can be said for maintenance teams who might occasionally test pieces of equipment for excessive vibration or temperature, but these checks sometimes occur weeks apart. These efforts require too much time, and the resolution of the data is too infrequent to catch down to the minute problems.

Access to real-time data has immediate impacts on any manufacturing process. It provides manufacturers with the ability to track productivity and helps quickly answer questions like, “Are you getting optimal throughput? If no, why not?” It also provides the ability to monitor equipment health for maintenance purposes to get ahead of problems before they cause a breakdown.

Start small, think big-scale fast

All too often, corporate strategies paint a picture of what is possible in the future but lack an activation plan to get started. The path to a smart factory is about momentum, so getting started by piloting ideas and collecting actionable data lets you decide which projects deliver enough value to graduate to the next level.

Banner has solutions to start small while providing scalability to scale the best ideas. SmartSolutions™ Starter Kits begin at less than $1000, incorporate battery-powered wireless sensors, and provide everything else you need to start monitoring equipment. Different kits are offered depending on the type of sensor you need. Options include pressure, tank level, vibration, temperature and humidity, as well as all four sensors in one kit. These kits include the wireless gateway with an embedded cellular modem to send data to the cloud. A 3-month trial subscription to cellular data plans and Banner CDS (Cloud Data Services) is included allowing you to immediately view your information from a dashboard on the web.

An example of one of Banner Engineering’s SmartSolutions starter kits. (Image source: Banner Engineering)

An example of one of Banner Engineering’s SmartSolutions starter kits. (Image source: Banner Engineering)

Once you discover what ideas and data are the most valuable, Banner makes it easy to continue building momentum and scale up by allowing more sensors to be easily added to existing Starter Kits. Our products provide plenty of room to grow your smart factory initiatives, with the ability to build systems that can monitor thousands of data points.

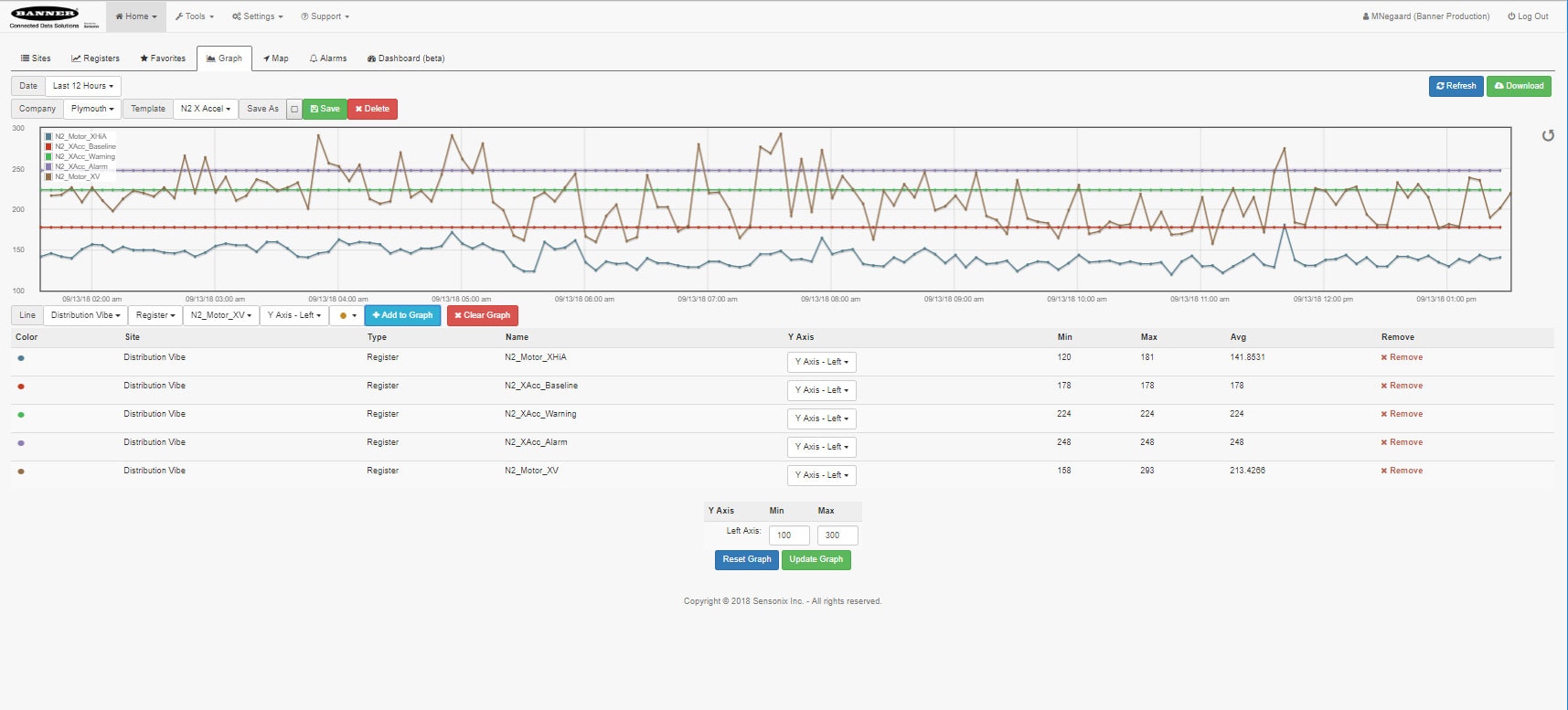

In these example dashboard images, a motor is being monitored by one of Banner Engineering’s SmartSolutions starter kits. (Image source: Banner Engineering)

In these example dashboard images, a motor is being monitored by one of Banner Engineering’s SmartSolutions starter kits. (Image source: Banner Engineering)

Hear more on the future of factory automation from Banner Engineering in the new three-part Future Factories series hosted by DigiKey.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum