Count those Coulombs for Lithium Battery Fitness! Details Inside!

It used to be engineers would ask themselves how many laptops is enough? Now that question is, how many tablets do we need? My newest is a nice 12 inch Android Marshmallow convertible RCA tablet with a detachable keyboard. During meetings it looks like a normal slim laptop as I type important notes to myself like “restructure marketing to be more solutions-based” or “eat more chicken”. Sometimes I have to show a presentation to the rest of the team, so I detach the display from the keyboard and explain my graphics. Of course, nobody is listening to what I’m saying (just like my parents) and instead I’m asked, “what is that?” Sadly, they are not referring to my brilliantly persuasive PowerPoint skills but want to know about my tablet.

So, we discuss my tablet and I’d show them part of “The Adventures of Buckaroo Banzai Across the 8th Dimension” before breaking for lunch. Later when the tablet’s screen is dark I’d briefly touch the power button to wake it from sleep, hold my breath, and hope it hasn’t frozen. It’s called the Android Sleep of Death, or SOD (if it has an acronym it must be true). No problem, I know how to fix this – next day I charge the tablet to 100%, then let it discharge down to 2% with the screen on while playing a movie (“Buckaroo”), then I charge it all the way to 100% without stopping. I do this twice a year and the tablet stops crashing and becomes more stable. And the question is, why does this work?

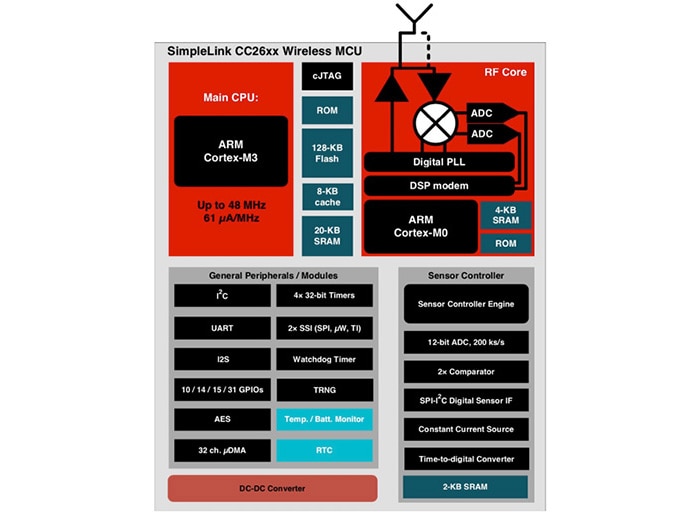

I recently wrote an award-winning (in my own mind) three-part series for DigiKey on designing wearables and in Part 2, “Protect and Recharge Batteries for Long Life”, I examined lithium-ion batteries and battery gauges. See, unlike what many on the internet believe, the main processor of a tablet or wearable doesn’t keep track of the battery’s level and health, a separate chip does that. Most portable battery-powered devices use lithium-ion batteries, and Maxim Integrated battery management chips are found in many of them. Even when you think your portable device is turned off, the battery management chip is still active, constantly monitoring the state of the lithium-ion battery.

Measuring the battery level of a rechargeable lithium-ion battery isn’t a simple matter of percentage of maximum voltage. If a 3.7 volt lithium battery is at 3.1 volts, the battery isn’t at 84 percent because in many cases a lithium-ion cell is considered dead at 3.0 volts. But 14 percent isn’t correct, either. So how does one really know the available capacity of a lithium-ion battery?

It’s called coulomb counting. A battery management chip basically counts the coulombs into and out of the battery. Or rather, coulomb counting keeps track of the total current flow and voltage over time into and out of a lithium-ion battery to determine the battery’s available capacity.

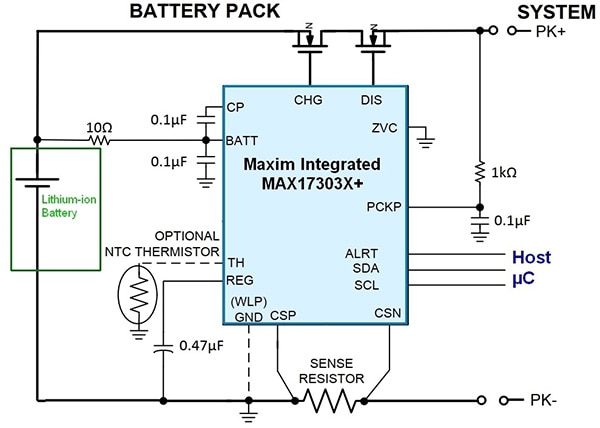

A simplistic example would be if a fully charged battery provided 200 milliamps (mA) for 48 hours until depletion, the battery capacity would be 200 mA x 48 hours = 9.6 amp-hours (Ah). In reality, coulomb counting is more complex, which is why it needs a dedicated chip with the intelligence to do the math. The Maxim Integrated MAX17303X+ is such a chip. In the application circuit shown in Figure 1, the current flowing into and out of the lithium-ion battery is measured across the sense resistor at the bottom.

Figure 1: The Maxim Integrated MAX17303X+ lithium-ion battery management chip easily interfaces to a microcontroller and keeps track of all current into and out of the battery (Image source: Maxim Integrated).

Figure 1: The Maxim Integrated MAX17303X+ lithium-ion battery management chip easily interfaces to a microcontroller and keeps track of all current into and out of the battery (Image source: Maxim Integrated).

The MAX17303X+ is programmable and interfaces to a microcontroller using an I2C serial interface. It has an internal processor for battery calculations along with RAM and non-volatile memory. The chip keeps track of all current and voltage leaving the battery during discharging and entering the battery during charging. The company enhances coulomb counting with ModelGauge m5, its own proprietary battery gauge algorithm.

Non-volatile memory stores the maximum and minimum voltage, current, and temperature of the battery along with collected battery state information that needs to be maintained if battery power is lost. This is important as many lithium-ion batteries contain protection circuits that prevent deep discharge by disabling the battery at very low voltages until charged.

Most important for consumers, the MAX17303X+ keeps accurate track of the battery state for the battery gauge. The state of charge (SOC) is calculated as a percentage of the battery’s available capacity at that time in Ah against the battery’s maximum measured capacity. The state of health (SOH) is the battery’s maximum available Ah verses the battery’s maximum capacity when new.

Still, no matter how smart the battery management chip, errors are unavoidable, so to keep the battery gauge accurate it must be calibrated. Calibration means discharging the battery from 100 percent down to almost empty. This gives the MAX17303X+ an accurate understanding of the discharge behavior. The battery is then charged up to 100 percent, so the chip learns its charge capacity. At this point the battery gauge is calibrated.

So, I took my RCA tablet and calibrated the battery, with Buckaroo Banzai again helping me keep the screen on as I discharged to 2 percent, preventing the SOD. I then charged to 100 percent, then turned the tablet off for five minutes. This gives the battery management chip time to read the fully charged battery voltage under minimal load. After this, the tablet stopped crashing. Not only that, but it was more responsive and snappier to the touch.

How does that work?

Why does calibrating the battery gauge stop the tablet from crashing? My theory is that on button press to wake from sleep, the host microcontroller first reads the battery state from whatever battery management chip it's using. I’m thinking the host microcontroller firmware is reading unexpected data (read: not coded for), and unfortunately the firmware doesn’t have an exception handler for the issue so the tablet freezes. Something similar is happening while the tablet is active, and it is periodically monitoring the battery management chip’s data.

This raises the question, “Why not calibrate your battery all the time?” Because lithium-ion batteries are permanently damaged by deep discharges, so two or three times a year is enough. This applies to anything with a rechargeable lithium-ion battery, including wearables and Internet of Things (IoT) endpoints.

So, calibrating the battery may increase the stability of a lithium-ion system. It is certainly necessary for an accurate battery gauge, and it is sorely needed if we ever expect to reach across the 8th Dimension.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum