Coin & Button Battery Proliferation: Necessity or Poor Design?

Coin and button batteries are widely used sources of basic, primary (non-rechargeable) power for many highly portable electronic products as well as remotely located Industrial Internet of Things (IIoT) monitoring devices. With the proliferation of ultra-low-power designs, these batteries can provide power for months and even years, which is pretty amazing. But just wait until you need to replace one though, and then the “fun” (translation: aggravation and frustration) sometimes begins.

Why? Because if you are lucky, the battery you need is a standard, widely available one. While that is often the case, it is also not always the reality. Button and coin batteries come in hundreds of sizes (diameter and thickness combinations) and with various basic chemistries (such as silver oxide or lithium), nominal voltages, and milliamp-hour (mAh) capacity ratings. Some of their dimensions differ by only a fraction of a millimeter between models, but that’s enough to make the replacement not fit properly or work reliably.

In an ideal world, the design engineer would allocate a certain amount of space for the battery early in the design phase, pick a fairly common model with the right voltage and capacity ratings, make sure the final design has the required physical room, and keep to the power budget as the design progressed. But engineering is the art of transforming objectives into reality while making tradeoffs and compromises, and sometimes unexpected design “stuff” happens which requires modifying the original plan, even though it was made in good faith.

Several years ago, I spoke with the designer of a consumer product I owned which used a hard-to-find coin battery. I asked him flat out: “Why did you do that?” His answer was simple (I’m paraphrasing here, of course): “When we closed in on the design’s final form factor, we realized we didn’t leave enough space for the battery we wanted to use initially. The easiest thing to do was find a battery with the right voltage/capacity specifications but which was a little smaller.” He added that it was a special order, longer-lead item on their BOM, but that was OK as they still had final product tooling to do anyway. In short, purchasers of this product were left out of the picture when the decision was made, sorry.

Checking those battery numbers

Sometimes, the battery number is one which has multiple cross references, and that adds to the replacement challenge. Some of these cross references are exact, while others are close and differ in chemistry or mAh capacity but will still work—at least for a while.

Even so, knowing the battery name and number may not be enough. I have a small, giveaway promotion keychain light which needed a new battery (Figure 1). Of course, it’s likely not worth the cost of replacing the battery (since it was free, I can’t complain). Still, as an engineer, I felt compelled to at least see if a replacement was available, and at what cost.

Figure 1: This free LED keychain made very clear to me that unusual coin cells can be a major challenge when a replacement is needed. (Image source: Bill Schweber)

Figure 1: This free LED keychain made very clear to me that unusual coin cells can be a major challenge when a replacement is needed. (Image source: Bill Schweber)

I figured this would be easy, since the battery was clearly stamped on the case with a vendor name (Lumatec), a model number (AR18), and voltage (4.5 volts) (Figure 2). How thoughtful. Note that as an example of extreme cost savings, one LED lead is simply connected to the battery using cellophane tape, which you can consider as either brilliant minimalist design or maximally shabby engineering—or perhaps it is both at the same time.

Figure 2: A closer look showed the good news: the battery has a vendor name, model number, and even nominal voltage clearly marked; note the cellophane tape used for connecting the LED lead to the battery. (Image source: Bill Schweber)

Figure 2: A closer look showed the good news: the battery has a vendor name, model number, and even nominal voltage clearly marked; note the cellophane tape used for connecting the LED lead to the battery. (Image source: Bill Schweber)

I searched online and could not find this vendor name or battery number, so I took it to the next step: I measured the battery (Figure 3), and found it had a 23 millimeter (mm) case diameter plus a rim that brought the overall diameter to 25 mm and a thickness of 6.5 mm. Then I unsuccessfully searched various coin cell vendor sites looking for 4.5 volt battery with those dimensions. Finally, I realized I had wasted enough time and needed to move on before obsession took over.

Figure 3: I took my search to the next level by measuring the various battery dimensions, as a logical first step in my online replacement hunt. (Image source: Bill Schweber)

Figure 3: I took my search to the next level by measuring the various battery dimensions, as a logical first step in my online replacement hunt. (Image source: Bill Schweber)

My experience is that there are about five to ten coin and button batteries which account for the bulk of devices I have used, and for which you can buy extras at local stores. They are also widely available through distributors for OEM quantities.

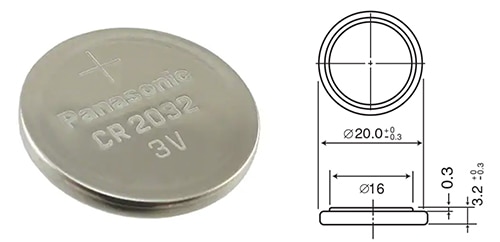

Among my personal favorites is the CR2032 from Panasonic. This 3 volt, 225 mAh, 20.0 mm lithium-manganese-dioxide coin cell (Figure 4) is so widely used that DigiKey lists nearly three million in stock.

Figure 4: The Panasonic CR2032 coin cell (left) is widely used and also widely available. Its dimensions make it suitable for many applications (right), and it also has a substantial 225 mAh capacity rating. (Image sources: Panasonic)

Figure 4: The Panasonic CR2032 coin cell (left) is widely used and also widely available. Its dimensions make it suitable for many applications (right), and it also has a substantial 225 mAh capacity rating. (Image sources: Panasonic)

Another one I like to see is the 357-303VZ from Energizer Battery Company; a 1.55 volt, 150 mAh, 11.6 mm silver-oxide battery. I keep a few of these battery types and some others in my personal stock, to avoid having to go out for a replacement at the local store late or in bad weather. Given their shelf life of five or more years, that’s a reasonable inventory position to take.

My plea to designers is simple: please, stick with the leading coin and button cell models, unless you have a truly compelling reason to deviate and not to do so. You’ll be doing yourself a favor, your supply chain will be easier, and your end customers will be happy. Just as important, they won’t be angry at engineers in general for doing something which aggravates them and complicates their lives for no apparent reason.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum