Fuel-Gauge ICs Simplify Li-Ion Cell Charge Monitoring

Contributed By Electronic Products

2014-01-15

For circuits relying on lithium-ion cells, determining the amount of charge remaining in a cell requires specialized techniques that can complicate the design of energy-harvesting applications. Engineers can implement these techniques with MCUs and ADCs normally used in these applications, but at the cost of increased complexity. Instead, engineers can easily add this functionality to existing designs using dedicated "fuel-gauge" ICs available from manufacturers including Linear Technology, Maxim Integrated, STMicroelectronics, and Texas Instruments.

Determining the state of charge (SOC) in lithium-ion batteries is essential yet challenging due to the great variability in capacity not only across different cells, but also in the same cell. As a Li-ion cell ages, it loses its ability to store charge. Consequently, even if fully charged, an older cell would deliver usable voltage for a shorter period of time than a newer cell. With any Li-ion cell, SOC varies greatly depending on the temperature and discharge rate, resulting in a unique family of curves for any particular cell (Figure 1).

The nature of the characteristic output voltage curve for Li-ion technology complicates determining SOC. With other technologies, open-circuit voltage (OCV) offers a reliable indicator of state of charge. With Li-ion cells such as the Panasonic VI series, however, the relatively-flat voltage output curve found with these cells makes this method more challenging (Figure 1). Instead, Li-ion battery-monitoring methods typically rely on coulomb counting or impedance measurement; the former tracking the amount of current discharged over time, while the latter exploits the relationship between SOC and internal impedance of a cell.

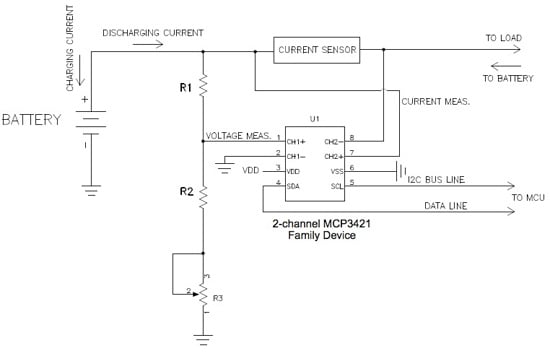

Each of these methods requires careful and continuous measurement of battery output current and voltage, followed by careful analysis of those values compared to models that relate voltage to SOC. For energy-harvesting applications, engineers can often take advantage of MCUs and ADCs, devices already in place to provide core functionality for the energy-harvesting application. An ADC such as the Microchip Technology MCP3421 can be used to capture measurements of current and voltage output for analysis by the MCU (Figure 2). In turn, the MCU executes SOC algorithms or compares measured values with ideal values in an SOC lookup table, or relies on some combination of algorithmic analysis and data lookup.

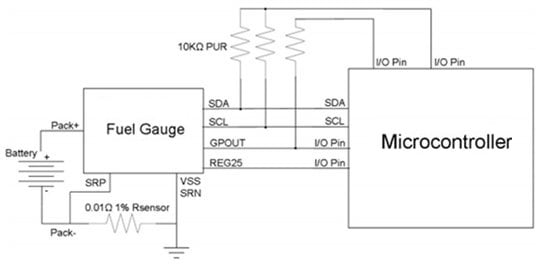

Fuel-gauge ICs provide an integrated solution, replacing ADCs and discrete components with a single device able to execute sophisticated SOC-estimation methods and transmit the results to an MCU (Figure 3). Most fuel-gauge ICs implement coulomb-counting methods, measuring voltage across a current sense resistor to track current discharge needed to estimate SOC for a Li-ion cell.

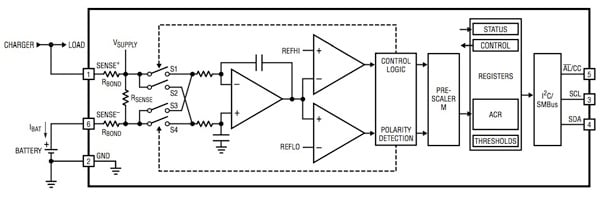

Advanced fuel-gauge ICs such as the Linear Technology LTC2941-1 combine a dedicated coulomb counter with an on-chip sense resistor that is temperature-compensated to enhance accuracy. Here, the coulomb counter monitors the voltage developed across the internal sense resistor, integrating the measured data to estimate charge (Figure 4). The LTC2942-1 includes the functionality of the LTC2941-1 with the added ability to perform temperature and voltage measurements.

Fuel-gauge ICs typically transmit SOC as a single value. Alternatively, Linear's LTC4150 fuel-gauge IC transmits its results as a series of output pulses corresponding to a fixed quantity of charge flowing into or out of the battery.

Although coulomb counting is a commonly used method in fuel-gauge ICs, many of these devices combine coulomb counting with periodic voltage measurements, typically used to recalibrate the results to account for temperature or cell-aging effects. The Maxim Integrated DS2786B counts charge flowing into and out of the cell as the cell charges and discharges. When the application becomes inactive, the DS2786B performs a cell OCV measurement after delaying a sufficient amount of time for the cell voltage to settle. Based on the OCV measurement, the device adjusts its stored coulomb-count value using its on-chip OCV cell model. Stored in the DS2786B's EEPROM, the model relates SOC to voltage at several specific points on the voltage curve (Figure 5).

At power-up, the DS2786B performs an initial voltage measurement and uses the OCV cell-model data to determine a starting point for its charge measurement. The next OCV measurement allows the device to correct any errors. As the cell ages, the device adjusts its results to account for changes in capacity.

The STMicroelectronics STC3115 uses its proprietary OptimGauge adaptive algorithm to track SOC and update its on-chip battery model to account for temperature, aging, and differences in cell characteristics from those stored in its on-chip profiles for different battery types. An on-chip sigma-delta ADC measures battery voltage, current, and temperature values needed for SOC tracking and model updates. During periods of high-rate charge or discharge, the device uses coulomb counting to estimate SOC.

For power-sensitive applications, the device also includes a low-power operating mode that disables current sensing. Engineers can program the STC3115 to switch between the normal and low-power operation to maximize accuracy during active periods and minimize power consumption during standby periods.

Designed for low-power operation, the Texas Instruments bqJUNIOR™ series features multiple low-power operating modes, consuming less than 90 µA in active mode, less than 2.5 µA in sleep mode, and under 20 nA in deep sleep with data retention. The bqJUNIOR devices such as the bq27210 provide capacity information compensated for battery age, temperature, self-discharge, and discharge rate. During each discharge cycle, these devices automatically recalibrate values stored in on-chip registers for current, capacity, time-to-empty, SOC, cell temperature, cell voltage, and status, among others.

Texas Instruments also offers fuel-gauge ICs that implement TI's proprietary Impedance Track method, which uses cell impedance measurements to estimate SOC for Li-ion cells. Impedance tracking avoids the need to model cell performance or perform recalibration sequences to update on-chip model parameters. Impedance Track ICs such as the TI bq27421-G1 and bq27425-G2 are able to calculate remaining battery capacity without modeling or learning and provide high accuracy for the entire life of the battery and across different operating conditions.

Conclusion

Accurate estimation of Li-ion cell SOC relies on careful measurement of cell voltage and current. For some energy-harvesting applications, engineers can use MCUs and ADCs already in place to perform the required measurements and analysis. Single-chip fuel-gauge ICs incorporate sophisticated measurement methods to provide a simple solution for SOC determination. Using available fuel-gauge ICs, engineers can easily augment energy-harvesting applications with functionality needed to deliver accurate information on Li-ion cell charge and capacity.

For more information on the parts discussed in this article, use the links provided to access product information pages on the DigiKey website.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.