Quickly Implement a Remote Industrial IoT Cellular Endpoint Using an LTE Microcontroller and Router

Contributed By DigiKey's North American Editors

2020-02-19

As Internet of Things (IoT) applications expand, so too must the reach of their associated networks. While Wi-Fi, Bluetooth, and Zigbee can be available for convenient wireless networking near or inside an industrial facility, some Industrial IoT (IIoT) networks require remote monitoring and control of systems in the field that can be many miles away or widely dispersed—often in locations that are difficult and time-consuming for maintenance technicians to reach. For these situations, cellular networking is the best wireless solution.

This article explains the need for remote data monitoring and control over cellular in some IIoT applications located many miles away and describes the advantages of a remote IIoT node that must conserve power with minimal or no maintenance. It then introduces a cellular microcontroller from Nordic Semiconductor that can transmit data over an LTE network to a DIN-rail mounted cellular router from Phoenix Contact.

Expanded IIoT networking

Conventional IIoT networks are set in a single location such as a manufacturing facility, automated warehouse, or outdoor park. Networking to the hub can be wired as with industrial Ethernet, or wireless as in Wi-Fi or Zigbee. This is easily managed from a central location where there is ready access to the location of endpoints on the IIoT network allowing for efficient maintenance or replacements.

As the IIoT has expanded, so too have the use cases. For increased efficiency and immediate control of networks, facilities managers need to actively monitor and control remote systems with minimal latency between the remote system and the hub at headquarters. Transportation systems such as trains, subways, and interstate trucking can benefit by monitoring various sensors on the engine or electric motor along with fuel and energy consumption, speed, and distance, as well as GPS positioning for tracking location and estimating time to destination. This data is sent to the main facility or corporate headquarters and analyzed. The data can be used almost immediately to save time and money by improving efficiency and preventing failures, thereby reducing costs while increasing reliability.

Oil and gas pipelines benefit from IIoT networking by monitoring volume and pressure in the pipeline, along with environmental conditions such as temperature, barometer readings, and humidity. Precision GPS location monitoring along with vibration and gyroscope sensors can detect movement on the pipeline due to external forces such as seismic events. In some cases flow through the pipeline can be remotely restricted or stopped in response to a detected emergency situation such as an earthquake. Equipment can run self-diagnostics and the results sent to the factory for analysis. As these pipelines can be located many thousands of miles from headquarters in harsh environments such as the Arctic Circle, it’s important for the endpoint to have a communications network that is completely reliable.

Enter cellular IoT

To meet these needs, IIoT networking has expanded to send data over existing long term evolution (LTE) cellular networks. This allows an IIoT endpoint to be placed almost anywhere in the world where LTE connectivity is available, as long as a source of power can be applied and maintained, with the added advantage that the cost and effort of cellular network maintenance is the responsibility of the cellular carriers. Because these systems can be located in remote, unmonitored hard-to-reach locations, the remote cellular IIoT endpoint must be reliable and resistant to hacking or physical tampering.

The first step toward a reliable embedded system for IIoT is to keep the system simple while minimizing power. Keeping the system simple reduces the number of failure points. Lowering power consumption improves reliability by reducing heat, which extends the lifespan of most semiconductor devices, as well as improves the battery life of battery-powered IIoT endpoints.

To meet these requirements Nordic Semiconductor has introduced the nRF9160 LTE cellular IoT microcontroller. The nRF9160 simplifies cellular IIoT endpoint development by incorporating a complete on-chip LTE modem compliant with the latest cellular IoT and machine-to-machine (M2M) data standards (Figure 1).

<Figure 1: The Nordic Semiconductor nRF9160 LTE cellular microcontroller is based on the Arm® Cortex®-M33 core. It has all the peripherals necessary to build a cellular IoT endpoint including an LTE modem and GPS module. (Image source: Nordic Semiconductor)

<Figure 1: The Nordic Semiconductor nRF9160 LTE cellular microcontroller is based on the Arm® Cortex®-M33 core. It has all the peripherals necessary to build a cellular IoT endpoint including an LTE modem and GPS module. (Image source: Nordic Semiconductor)

The Nordic Semiconductor nRF9160 is based on a 64 megahertz (MHz) Arm Cortex-M33 processor core, which specifically targets low power IoT applications. The Cortex-M33 supports single-cycle multiply and accumulate (MAC) operations and has single-precision floating point unit (FPU) instructions, a hardware divide, and single-instruction multiple data (SIMD) operations. This is useful for quickly processing sensor data as in sensor fusion calculations. The Cortex-M33 is highly deterministic even when entering and leaving low power modes, with support for real-time operation.

The nRF9160 microcontroller has 1 megabyte (Mbyte) of on-chip flash for application firmware and 256 kilobytes (Kbytes) of low-leakage RAM. It has an Arm TrustZone subsystem for cryptographic operations including AES encryption, a true random number generator (TRNG), and secure password management. This is useful for verifying encrypted data communications as well as firmware tampering detection. Standard on-chip serial interfaces include SPI, I2C, and UART ports for interfacing to external sensors and actuators. An eight-channel, native 12-bit (14-bits with oversampling) analog to digital converter (ADC) is useful for analog sensor reading.

The nRF9160 also has an on-chip GPS receiver optimized for low-power IoT endpoints. This is especially useful for mobile endpoints such as trucks and trains. It is also useful for systems that may unintentionally shift in position due to seismic activity, or for detecting intentional movement if the endpoint is mounted on a movable device such as robotic equipment. The GPS receiver shares the on-chip RF transceiver with the LTE modem. If both the LTE modem and the GPS receiver are active, the shared RF transceiver is time-multiplexed with the GPS module and the LTE modem, with the LTE modem given priority.

The LTE modem on the nRF9160 consists of a host control processor with dedicated flash and RAM memory, a baseband processor, an RF transceiver with external 50 ohm (Ω) antenna pin, and a SIM card interface. For increased reliability of communications the LTE modem has its own diagnostics and fault detection. The LTE modem supports low power M2M and IoT data communications protocols including Cat-M1, Cat-NB1, and Cat-NB2.

To exchange data over an LTE network, the LTE modem requires a standard SIM card containing the wireless network, telephone number, and subscriber information. The nRF9160 LTE host processor has an external universal integrated circuit card (UICC) interface, also called a SIM card interface, for connecting to any activated SIM card that is compatible with LTE-M or Narrowband IoT (NB-IoT) data transmission standards.

Each nRF9160 LTE endpoint will require the purchase of a SIM card with an appropriate data plan from a cellular carrier. A SIM card and cellular data plan for networked IoT devices can be conveniently purchased from DigiKey. Plans are available with data capacities from 300 Kbytes up to 5 gigabytes (Gbytes) per month.

The nRF9160 can operate from 3.0 to 5.5 volts, making it suitable for use with battery-powered IIoT endpoints with a 3.7 volt lithium battery. Operation at 3.7 volts is recommended as most of the device specifications are at a 3.7 volt supply voltage. Most of the power domains for the peripherals and processor modules of the nRF9160 are configurable and power can be turned on and off under firmware control. This allows developers to fine-tune the current draw to meet specific application requirements.

The nRF9160 has a power saving mode (PSM) that puts the core in idle (core register states preserved), the LTE modem off, and most peripherals off. For an IIoT endpoint that must keep track of time, with the RTC in PSM, the nRF9160 draws only 2.35 microamps (µA), an impressively low current draw for a battery-powered device.

The GPS module draws a considerable 47 milliamps (mA) when continuously tracking. However, it is more practical to run the GPS in PSM as it only draws an additional 12 mA. This would be appropriate for trains or trucks that require continuous real-time location monitoring. An even more economical mode is configuring the GPS to take a single-shot fix once every two minutes, which requires only 1.3 mA. This is appropriate for fixed nodes that only need to detect occasional movement.

When communicating using any LTE-M protocol the nRF9160 can transmit data as fast as 375 kilobits per second (kbps). The lower-data-rate NB-IoT protocol is as fast as 60 kbps. These low data rates conserve power while maintaining reliable communications between the endpoint and the hub. The LTE modem also supports transport layer security (TLS) allowing for secure, encrypted communications to help prevent man-in-the-middle attacks or unauthorized interception of transmitted data.

The nRF9160 operates in temperatures from -40 to +85°C, making it appropriate for extremely cold and most very hot environments.

The LTE radio provides up to 23 decibels reference to 1 milliwatt (mW) (dBm) of output power to the antenna. It is compatible with IPv4 and the latest IPv6, making it easily expandable to new IP addresses without the limitations of IPv4. The LTE modem also supports SMS text messaging. This allows the IIoT endpoint to send and receive text data similar to a cellphone, except instead of saying “hello” the messaging can be used to receive sensor data and send operational commands.

LTE endpoint development

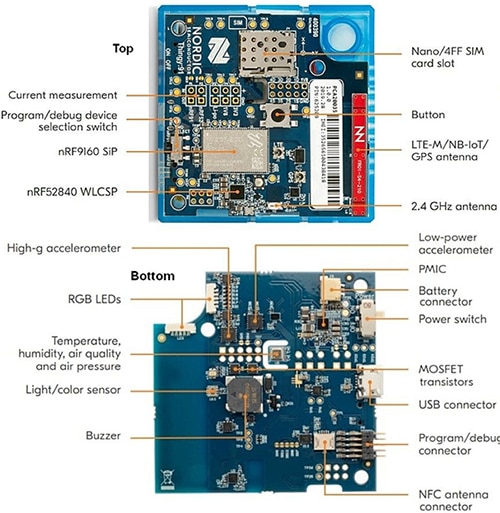

To support development for the nRF9160, Nordic Semiconductor supplies the nRF6943 Nordic Thingy:91 cellular development board (Figure 2). The board comes packaged conveniently as a kit in a bright orange box that can almost be deployed as-is for quick implementation.

Figure 2: The Nordic Semiconductor nRF6943 Thingy:91 is a full-featured cellular development kit with a plethora of sensors and pins to connect to external devices. It has a SIM card socket for a subscriber SIM card. (Image source: Nordic Semiconductor)

Figure 2: The Nordic Semiconductor nRF6943 Thingy:91 is a full-featured cellular development kit with a plethora of sensors and pins to connect to external devices. It has a SIM card socket for a subscriber SIM card. (Image source: Nordic Semiconductor)

The nRF6943 development kit comes with a rechargeable 1400 milliamp-hour (mAh) lithium-polymer battery that is charged through the available USB port. The USB port is also used to connect the nRF6943 to a PC for firmware development, programming, and debugging.

The nRF6943 Thingy:91 development kit comes with a number of on-board sensors including a low-power accelerometer, a high-G accelerometer, a light and color sensor, and a current measurement port. An environmental sensor detects temperature, humidity, air quality, and air pressure. Individual port pins are available for connecting to additional external sensors. In addition, the nRF9160 drives four power MOSFETs which can be used to drive small DC motors or high current LEDs. A magnetic buzzer and three RGB LEDs provide audio and visual feedback during development. There are also two pushbuttons that are programmable by application firmware.

Connecting to the headquarters hub

An IIoT nRF9160 endpoint can be placed anywhere in the world that LTE connectivity is available. The IIoT cellular endpoint can transmit data over a wireless carrier’s cellular network with the headquarters hub to a cellular router like the Phoenix Contact 1010464 4G LTE router (Figure 3).

Figure 3: The Phoenix Contact 1010464 cellular router is an industrial 4G LTE router with an integrated firewall and virtual private network (VPN) support. (Image source: Phoenix Contact)

Figure 3: The Phoenix Contact 1010464 cellular router is an industrial 4G LTE router with an integrated firewall and virtual private network (VPN) support. (Image source: Phoenix Contact)

This Phoenix Contact 1010464 4G LTE router is designed for harsh industrial environments and connects to the AT&T U.S.A. cellular network. A SIM slot is in the rear for a subscriber SIM card. The router is DIN-rail mounted for convenient integration into an existing DIN-rail system with a minimum of hardware configuration. The location of the router must allow it to receive a clear cellular signal. Both the IIoT endpoint firmware and this cellular router must be configured with the telephone numbers of each SIM so they can communicate securely and efficiently. The LTE router has a firewall for added security and can easily screen out unauthorized LTE access from non-authorized phone numbers as well as suspicious packets originating from authorized numbers. VPN support allows for more secure data communications. The LTE cellular router has a four-port switch on the front and communicates with the local network via Ethernet.

This combination of a low-power IIoT endpoint and an LTE cellular router allows easy communications between the headquarters hub and the industrial endpoint, with the speed of communications only limited by the available bandwidth of the cellular network.

Conclusion

As shown, IIoT networks can be easily expanded to include endpoints anywhere in the world. Using a low-power microcontroller with an integrated LTE cellular modem saves time and design costs, and once properly configured can transmit data to a cellular router at the headquarters hub 24 hours a day.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.